I got a sweet e-Ink tablet for music. It’s great! A4 sized (13.3”) with a foot pedal for page turning.

But getting music off of paper and into Musescore so I can implement my picky engraving preferences takes a bit of work. So I built a custom keyboard for the task. It’s a Planck EZ programmed with their online designer and Wally firrmware manager.

The first step was to get a layout I liked. Masking tape and marker were the starting place.

Then I had sets made by Thockfactory and Yuzu.

Thockfactory

The Designer

Their online designer is pretty easy to learn. A little bumpy, but it’s dealing with a lot of complicated design problems. It does an OK job of showing what your final layout going to look like. The shapes and fonts are high quality, but the colors are lacking.

Everything was the same price and it was just “normal” layouts available. Nothing weird like Planck or ErgoDox. I had to create my layout in a 102-key setup, being careful to match profiles within rows and get the homing bumps where they belong.

First Problem: Inscrutible Error

I had one hiccup when I tried to place an order and it didn’t work. It turned out one of the font files was too large. When I made a stripped-down version that contained only the glyphs I cared about, it worked fine. I figured this out on my own. The error message was useless. I’m not sure what someone who doesn’t know how to use pyftsubset to make a new font file would do.

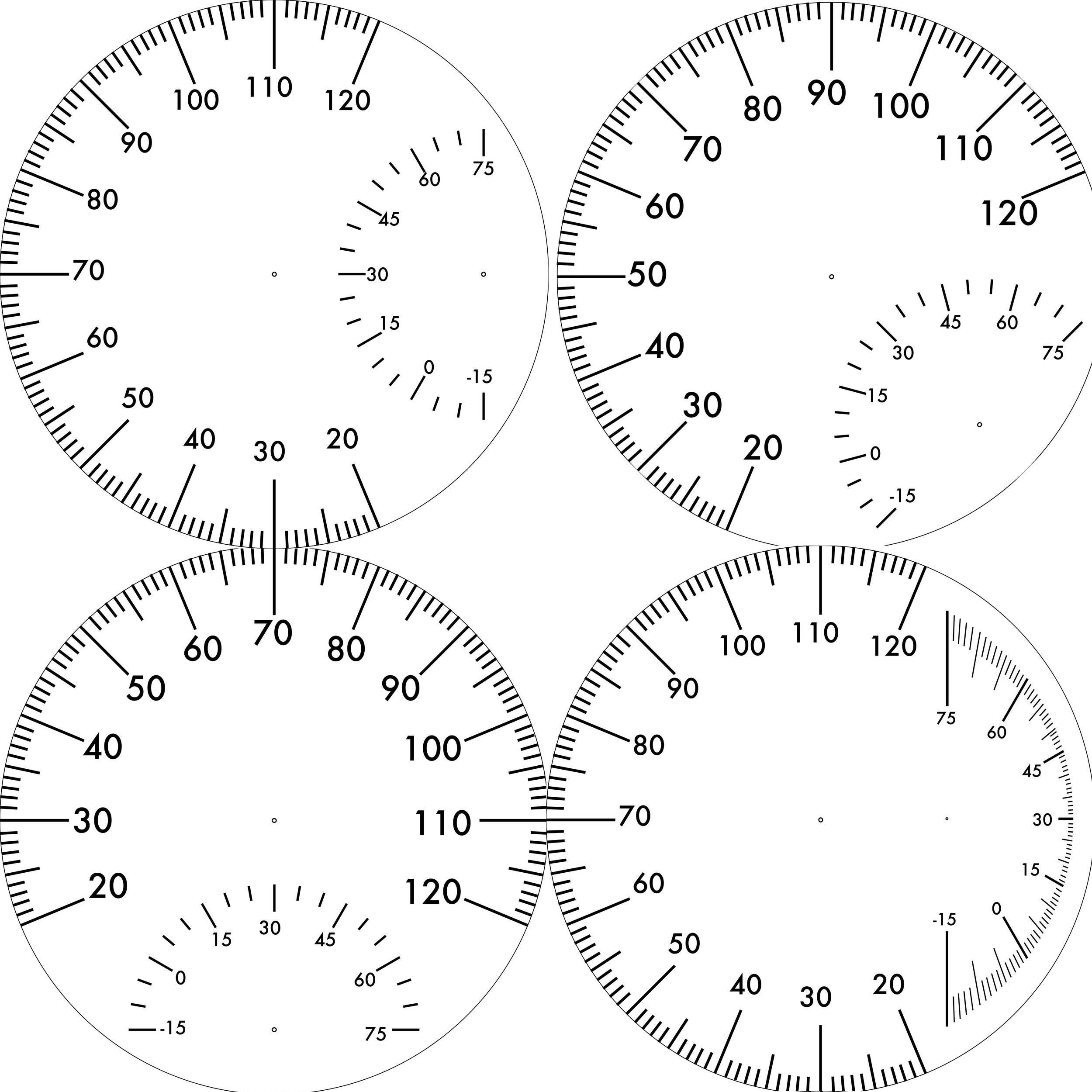

Second Problem: Wildly INACCURATE Color Matching

Check out this example from another project I did. The coaster was made by CafePress to match some decor in the room where the keyboard lives. CafePress did a great job on color match, but look at Thockfactory’s keycaps sitting on top.

The green is OK. The orange is… almost acceptable. But that yellow! Tragic.

THIRD Problem: They’re Not Available anymore?

I figured if I’m not trying to match any color, what harm? I just picked some colors and made my keycaps. But when I tried to make a replacement set with larger legends, I hit their maintenance page. They were supposed to be back online in fall 2024. Then Winter. Then March. Then April. Today it just says “We’ll be right back!” I don’t know if they’re ever coming back.

The Keycaps

They’re nice. Colors are uniform in tone (even if it’s not the hue I was expecting), and the legends are crisply printed. It arrives packed neatly in a tray to keep everything organized for an easy installation. If they could fix the color thing and take down the maintenance page, they would have a very good product.

YUZU KEYCAPS

The Designer

It’s as easy to use as Thockfactory. One thing it has going for it is kecap sets to fit odd layouts like the 47-key Planck I’m using. No wasted keycaps and no fussing over profile shapes.

The colors aren’t quite as flexible. You have to pick from one of the plastic colors they have available. The glyphs also aren’t quite as flexible. You have to use something that’s in a font set. I was able to upload the Leland font for all of the music symbols you see, but I couldn’t do the ejector seat like the Thockfactory board.

The Keycaps

Very nice. The legends are crisp, the colors are uniform, and the weight is nice. They arrive neatly packaged in a custom plastic tray made to hold the layout you ordered. Then the whole thing is in a pretty Yuzu-branded box with shrink-wrap. Very tidy.

Comparison

Both services sent me a set of perfectly serviceable keycaps. It’s incredible that I can choose from multiple purveyors to get a one-off print of a set of custom ABS keycaps. Depending on what’s important to the project, I would use either one of them again. For design options and graphics, Thockfactory works better, but the colors on Yuzu were much more faithful. If color matching matters, stick with the closest match you can find on Yuzu.